Dynamic 732T Motor Grader for Heavy-Duty Operations

Product Feature

There is a proportion differential in the original imported drive rear axle. This guarantees that when wheels on one side slip, wheels on the other side still can have enough traction. Middle and rear wheels are equipped with the planet type reducer. Performance of working is stable and reliable.

Using gear transmission, balance box can transmit the power smoothly and has reliable performance.

Front axle is steering driven axle. Front axle bridge uses cascade welding structure. Biggest turning angles of inside and outside are both 50 ° . Wide swing angle of bridge and slant angle of front wheels make the front axle more adaptive for the bad road condition. Therefore the precision of flattening of the road is much higher.

Owning to double-circuit motor brake and wet-type multi - gear clutch, 732T grader brake smoothly, safely and reliably and can avoid maintenance and adjustments. (the original imported brake valve and pressure-limiting valve).

Automatic spring loaded parking brake system makes grader safer. Equipped with the accumulator, it will alarm automatically on the condition of low inner pressure, and work as emergency brake when the grader fails in parking.

As a result of full-hy draulic constant - current steering system, turning speed can't be affected by engine speed. And it is parallelled with emergency steering pump and steering pump. So when the engine cut out unexpectedly, the emergency steering pump will immediately work to maintain the normal work of the system. Therefore, the reliability of system's working can be greatly improved.

732T grader uses company - owned patent of blade rotary worm-gear box ( patent no. : ZL 01 2 32115. X). Blade rotary worm-gear box is equipped with the overload protection clutch. When blade overload, the coupling slips in order to eliminate the excessive load of spare parts

Working hydraulic system is controlled by constant pressure. Load sensitive control system (imlet variable pump ) lessens heat productivity and saves the energy consumption.

Working cushion device is equipped in the pipe of left and right lifting cylinder. If the blade is suddenly collided while working, over-high confining pressure in the hydraulic system will force the cylinder lifting the blade to avoid collision. Thus the abnormally over-large load can't have any effect on the spare parts and it prevents the accident of spare parts damaging at the time of collision with the huge stone while road construction of mine area.

Building up a comfortable environment by capacious driver cab, broad-minded view, instrument monitoring, three-stage alarm manipulating components located according to human engineering desin, three - direction adjustable seat, control console shifted according to the need of driver and etc. The cab has the function of falling object protective structures ( FOPS) and roll over protection system (ROPS).

Product video

Product detail diagram

Customer case

Product Specification

| Overall Dimension | |||||||||||||

| 1 | Length | 12500mm | |||||||||||

| 2 | Width | 3300mm | |||||||||||

| 3 | Height(To the top of the cab)() | 3700mm | |||||||||||

| 4 | Wheel base | 7760mm | |||||||||||

| 5 | Tread | 2650mm | |||||||||||

| 6 | Min. turning radius | 9000mm | |||||||||||

| Main Technical Specification | |||||||||||||

| 1 | Operating weight | 28000kg | |||||||||||

| 2 | Blade length | 4620mm | |||||||||||

| 3 | Blade height | 695mm | |||||||||||

| 4 | Blade width | 20mm | |||||||||||

| 5 | Max. lift above ground | 515mm | |||||||||||

| 6 | Max. grading depth | 735mm | |||||||||||

| 7 | Max. shoulder reach outside rear tire | 2260mm(R)/1950mm(L) | |||||||||||

| 8 | Traveling speed(Km/h),6 forward and 3 reverse, | ||||||||||||

| (1) forward | 5.5、8.6、13.3、20.3、29、43 | ||||||||||||

| (2) reverse | 5.5、13.3、29 | ||||||||||||

| Diesel engine | |||||||||||||

| 1 | Model | Cummins QSM11-C330 | |||||||||||

| QSM11-C330 | |||||||||||||

| 2 | Type | EFI,turbocharger,air-to-air cooling,temperature control independent cooling system | |||||||||||

| 3 | Rated output | 246(kW) | |||||||||||

| 4 | Rated speed | 2100(r/min) | |||||||||||

| 5 | Max. Torque | 1674(N.m)/(1400r/min) | |||||||||||

| Transmission case | |||||||||||||

| 1 | Model | 6WG260 (ZF technology) | |||||||||||

| 2 | Type | electro-hydraulic controlled power shift single handle operation,automatic transmission | |||||||||||

| 3 | Gear shift position | 6 Forward and 3 reverse gears | |||||||||||

| Axle and Tire | |||||||||||||

| 1 | Max. drawing force | 144kN | |||||||||||

| 2 | Size of tire | 18.00-25-28PR | |||||||||||

| Working Device Hydraulic System | |||||||||||||

| 1 | Model of oil pump | RR074BLS2520-3S1N2A1 | |||||||||||

| 2 | System pressure | 25MPa | |||||||||||

| 3 | Model of distribution valve | Walvoil DRFC22132 DPX100/5 | |||||||||||

| Walvoil DRFC22133 DPX100/5 | |||||||||||||

| 4 | Model of oil motor | Eaton 604-1113 | |||||||||||

| Steering System | |||||||||||||

| 1 | Type | Fore Tiredeflexion | |||||||||||

| 2 | Model of steering gear | Eaton Xcel45-320 | |||||||||||

| 3 | System pressure | 16MPa | |||||||||||

| Brake System | |||||||||||||

| 1 | Type of traveling brak | Full Hydraulic Wet Brakes | |||||||||||

| 2 | Model of brake pump | HPT2-35/HPT1-20/9 | |||||||||||

| 3 | System pressure | 6.9MPa | |||||||||||

| 4 | Type of parking brake | Hydraulically Operated Disc Brake | |||||||||||

| Oil Capacity | |||||||||||||

| 1 | Fuel(diesel) | 540L | |||||||||||

| 2 | Engine lubricating oil | 28L | |||||||||||

| 3 | Oil for converter and gear box | 35-40L | |||||||||||

| 4 | Oil for hydraulic system | 200L | |||||||||||

| 5 | Oil for driving rear axles | 35L | |||||||||||

| 6 | Tandem box | 2*60L | |||||||||||

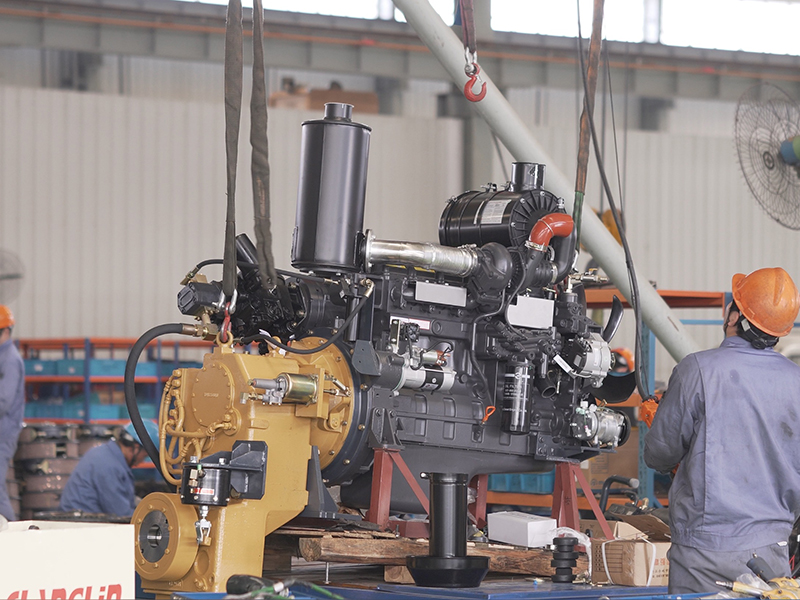

Production process

Shipping